Polybloc®, impervious graphite block heat exchanger

Brochures

pdf - 6 MB

-

Polybloc® graphite block heat exchangers are designed to meet the demanding requirements of corrosive processes in the chemical industry.

Versatile and Modular Design

Polybloc® graphite block heat exchangers are highly versatile and modular, suitable for heating, cooling, condensation, evaporation (falling film or forced circulation), and absorption applications.

They offer up to 350 m² of heat transfer surface, with block diameters ranging from Ø100 to 1500 mm and various drilling diameters and patterns to meet specific process requirements.

They are designed to handle pressures from full vacuum to 7 bar on both sides as standard, with options up to 16 barg on the service side and 12 barg on the process side.

The design temperature depends on the graphite material and the related resin, with extruded graphite (BS) up to 200°C, isostatic graphite with phenolic resin (XBS) up to 220°C, isostatic graphite with PTFE resin (XTH) up to 250°C and isostatic graphite with carbon resin (XC) up to 430°C.

-

Focus on material: Graphilor® 3 Grades

Mersen offers four grades of Graphilor® depending on the operating conditions of the chemical process:

- one grade for fine-grained extruded graphite (BS) and

- three grades for ultra-fine-grained isostatic graphite (XBS, XC, XTH).

Isostatic and extruded graphite are manufactured in-house at plants in the US and China. Impregnation is performed at the ACE Business Unit's plants.

-

4 impervious graphite grades

-

Phenolic resin impregnated extruded graphite

BS

Up to Ø1500 mm. It is suitable for most ultra-corrosive non-oxidizing applications involving hydrochloric, hydrobromic, hydrofluoric, or sulfuric acid...

Maximum temperature : 220°C -

Phenolic resin impregnated isostatic graphite

XBS

Up to Ø900 mm (monolithic) and Ø1500 mm (ML technology). It offers outstanding mechanical properties and is recommended for the toughest ultra-corrosive non-oxidizing applications.

Maximum temperature: 220°C -

Carbon impregnated isostatic graphite

XC

Up to Ø900 mm. It is a unique impregnation that can handle temperatures up to 430°C.

-

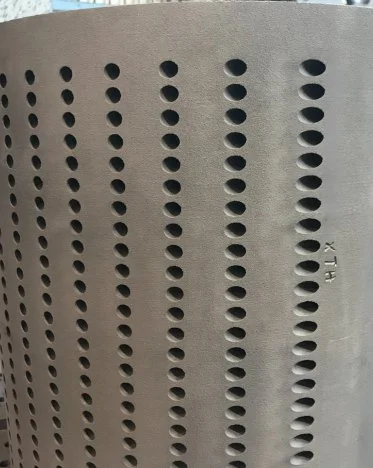

PTFE impregnated isostatic graphite

XTH

Up to Ø600 mm. It offers outstanding mechanical properties and is recommended for the toughest ultra-corrosive oxidizing applications such as mixed acid HF / HNO3 among others.

Maximum temperature: 250°C

-

-

Focus

The essentials of the Polybloc graphite block heat exchanger

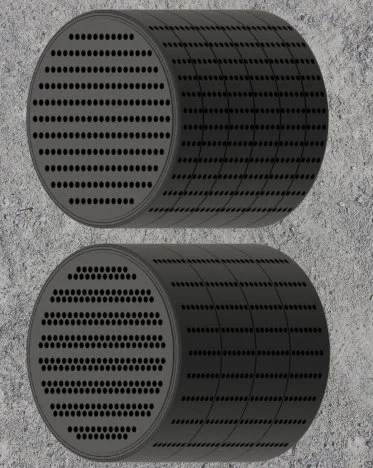

- Totally modular design: number of blocks, size of blocks and number of passes can be adjusted

- Different drilling diameters on process and service sides

- Maximum block diameter: 900 mm

- Graphite nozzles on product side

- Thermal expansion compensation ensured by tie rods and helical springs

- Design pressure: -1 barg (full vacuum) to +12 barg

- Design temperature: -60 to +430°C

- Heat transfer area: up to 350 m2

- Design: according to European PED, ASME code, Chinese Pressure Vessel code and other national pressure vessel codes on request

Optional Features

Optional features include gas/liquid separation chambers, headers with liquid distribution for falling film absorbers, erosion protection (Rigilor® carbon fiber cloth or wear block in amorphous carbon), dismountable headers for easy access, and custom drilling patterns for heavy fouling applications and crystallization.

- Versatile and modular design

- Easy maintenance

- Wide choice of graphite materials

- Individual block replacement

- High-pressure water jet cleaning and drilling for clogged blocks

-

Applications

What are graphite block heat exchangers used for?

Polybloc® graphite block heat exchangers are ideal for cooling, condensation, heating, evaporation, and absorption of ultra-corrosive chemicals, as well as facilitating heat transfer between two ultra-corrosive chemicals, making them best suited for single-purpose applications. These units are used in various applications, including:

- Heavy chemistry: Phosphoric acid, titanium dioxide, hydrometallurgy, vinyl chloride monomer, epichlorohydrin, plastics, viscose, aramid fiber, and more.

- Fine chemistry, specialty chemistry, and pharmacy: Active pharmaceutical ingredients, crop protection, fumed silica, silicones, flavors and fragrances, vitamins, and more.

- Carbon and stainless steel pickling.

-

Working Principle

How does a graphite heat exchanger work?

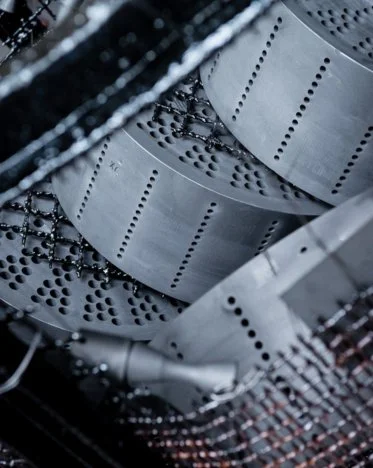

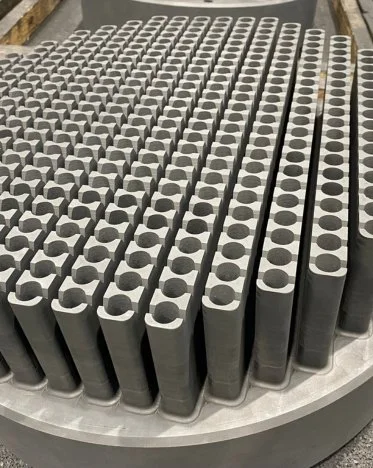

A graphite block heat exchanger is a process device which transfers heat from one medium to another without direct contact between fluids. Rows of holes are drilled through the blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the exchanger material left between the rows of holes which separate the mediums being used.

Graphite block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

The thermal performance of graphite block heat exchangers can vary significantly. It is therefore essential to select the type and size of graphite block heat exchanger that is the most adapted to the specific application and industrial process. There are a number of considerations including flow rate, pressure drop, risk of erosion, design pressure and temperature, materials compatibility, fouling, and many more that should be taken in account.

-

Construction and Materials

How is a graphite block heat exchanger manufactured?

The heat exchangers are constructed with impervious graphite blocks stacked inside a shell, with PTFE gaskets between the blocks and headers. The shell can be made from various materials, including carbon steel, stainless steel, glass-lined steel, rubber-lined steel, PTFE-lined steel, or reactive metals. Graphite headers at each end and O-ring gaskets or packing allow for differential thermal expansion, while springs maintain the blocks and gaskets under compression.

-

Our experts' answers

How to choose between a graphite block heat exchanger and a graphite shell and tube heat exchanger?

-

Contact

Contact our experts

Polybloc® graphite block heat exchangers are the most versatile and robust solution for corrosive applications. With a wide range of graphite materials, customizable designs, and easy maintenance, they are an excellent choice for process engineers and maintenance technicians looking to optimize their operations.

The Polybloc® graphite block heat exchanger is part of the Mersen range of heat exchangers resistant to corrosion and hot environments. Mersen designs and manufactures graphite cylindrical block Polybloc®, graphite shell and tube heat exchanger, cubic block heat exchanger, graphite plate and annular groove heat exchangers. We also manufacture graphite columns and graphite quenches. We propose a complete range of silicon carbide block, and shell and tube heat exchangers as well as steam jet vacuum pumps. We offer PTFE lined columns and vessels, as well as PTFE-lined steel pipes and fittings, and PTFE bellows We supply a complete range of graphite busting discs. We manufacture process equipment in reactive metals such as titanium, zirconium and nickel alloys.